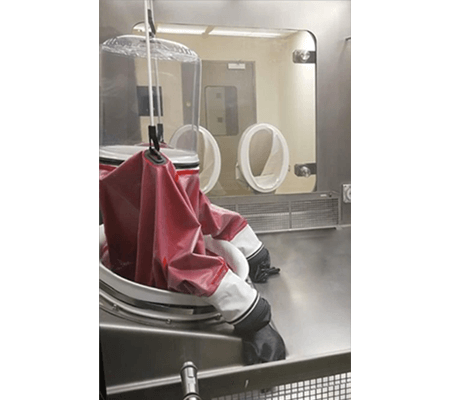

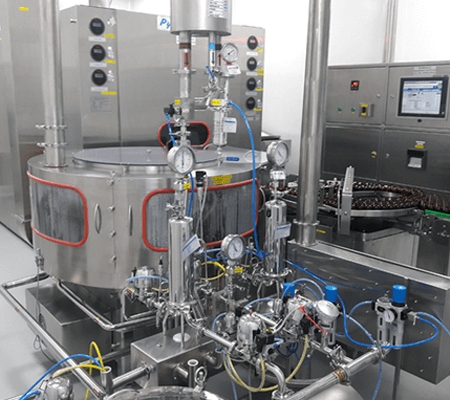

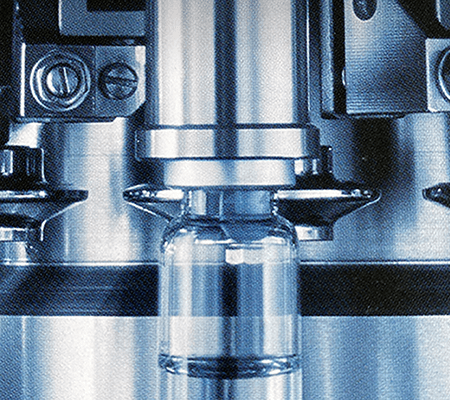

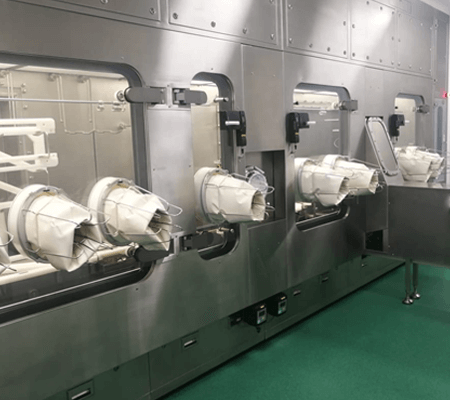

Klenzaids has historic links to global vaccine initiatives. Starting from building India’s first flock house clean room for SPF eggs to setting up Hoechst’ (now Sanofi) rabies bio-processing and injectables facility, Klenzaids has been involved with almost every vaccine. Today Klenzaids works closely with almost all diagnostic & vaccine producing institutions, companies and public healthcare establishments to provide technical solutions in this area of global significance. Kenzaids also provided clean, aseptic, sterile and contained environments for companies researching, testing, piloting, manufacturing and scaling-up Biopharmaceuticals like biosimilars and drug conjugates.

KLENZAIDS